Built, For You to Build.

The difference between a U-Build Locker and other wire mesh storage lockers, is baked right into our name: These are lockers designed for U to Build yourself.

That’s important if your project is located outside of a major city or you don’t have access to a specialist subtrade or installer.

U-Build Locker System are designed to solve that problem by providing Construction Managers a complete wire mesh locker system that can be installed by their own forces.

U-Build Lockers is the original manufacturer of our storage locker kits, not a distributor. This means that when you buy from us, you’re buying Factory Direct.

And our factory is special. Purpose-built to produce this product-line only, our production system utilizes the precision power of CNC laser cutting.

Using sheet metal laser cutters, our system:

- Precisely cuts the outline of our wall and door frames.

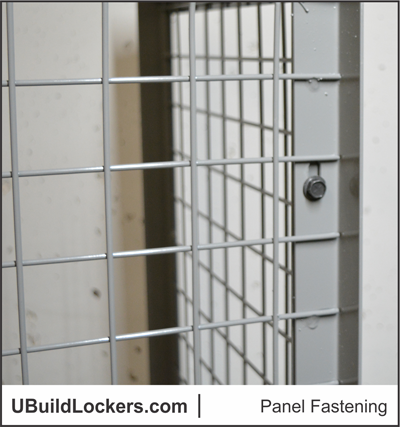

- Cuts holes in different places that are then used to connect the lockers together.

That combination creates the magic of our system: lockers that bolt together in a number of different configurations using simple tools and simple instructions.

Storage Locker Walls.

U-Build Locker walls are created by connecting one or more wire mesh panels together. Each panel is pre-cut with all of the standard holes you will need to make these connections.

Walls have to be strong, so U-Build Locker walls are made from:

Frame

- 12-gauge steel angle. 1.5" x 1.5" x 0.1046" / 2.66mm thick

- Laser Cut with standard connection holes

- Laser welded for a strong, spatter-free finish

Mesh Infill

- 10-gauge welded wire mesh infill ( 0.135" / 3.429mm diameter)

- Mesh spaced in 2" x 2" squares

- Mesh sheets are securely welded to the frame

Wall Panels are available in 2 heights and 5 widths.

We Make a Nice Door.

They are the part you see the most, use the most, and rely on the most to keep your stuff safe. The door is therefore a key component of any tenant storage locker.

U-Build Locker doors are made to install quickly and last for years to come.

Frame

- 12-gauge steel frame ( 0.1046" / 2.66mm thick)

- Laser cut to produce precision frame parts

- Laser-Welded square at all corners

- 3" Non-Removable pin hinge

- 3" Striker plate

Mesh

- 10-gauge welded steel mesh ( 0.135" / 3.429mm diameter)

- Mesh Laser-Welded to the door frame and crossbars

Security

- 4 X 3/8" Stainless steel locket hasps

- Reinforced with 2 x 3/8" steel crossbars

- Two 3" non-removable pin hinges + two secondary welds on the pin

Stainless Padlock Hasps

U-Build Bike & Storage Lockers feature the best hasp lockset in the business.

Every locker door is secured using 2 sets of 3/8″ diameter stainless steel eyebolts.

Each eyebolt is then secured in back with a 1 1/4″ UNC nylon-threaded nut.

The result is a lockset that cannot be unscrewed, cannot be cut with a bolt cutter, and will even give a portable angle grinder a hard time.

Fully Framed Ceilings.

Not all locker ceilings are built the same.

Locker-installation companies often use a loose mesh sheet that is then trimmed and fastened to the walls using rebar tie-wire or clips. It’s cheap for them, but also a cheap-out on you.

U-Build Lockers does it better by using a steel-framed mesh ceiling to form a strong, fully welded top to the locker.

Ceiling panels are then connected to the building wall, the locker wall and the ceiling panels of the adjacent lockers.

Creating a rigid upper structure, U-Build Lockers will stand rigid and steady throughout their many years of use.

Framed Transom Panels.

Good practice, and in many cases local regulations or the building inspector, further require that a mesh barrier be placed between the top of the locker and the underside of the slab.

Known as the Transom , the goal of this barrier is to prevent storage on top of the locker that will interfere with the operation of the sprinkler.

U-BuildLockers offers transom panels in 12″, 18″ and 24″ heights.

Fire Code Compliant

Many municipal authorities use either the IFC or NFPA fire codes as their own local fire code.

If your project has sprinklers, both of these codes require that the top of the locker ceiling be at least 18″ below the sprinkler deflector.

If you don’t have sprinklers, then the locker ceiling can be no closer than 24″ below the ceiling.

To determine the maximum height of the storage locker ceiling, simply measure the distance from the floor to the sprinkler deflector (or ceiling if you don’t have sprinklers).

Now subtract 18 or 24 inches to determine the locker ceiling’s maximum height.

Leveling Feet.

We’ve seen a few storage rooms. Enough to know that walls aren’t always straight, and floors aren’t always flat.

That’s why every wall panel is shipped with a levelling bracket that can be:

- Used at the bottom to level the wall on a sloped floor

- Used at the top to connect the panel to a sloped wall

Brackets are first loosely attached to the wall panel using the provided connector screw. Level the wall, drop the bracket and lock the screw in place. Finally, pin-bolt the bracket to the wall or floor to complete the install.

Powder Coat Finish.

All U-Build Lockers are finished with a thermoset powder coat finish.

We offer one color only: Medium Grey.

LEED friendly, powder coating is a dry, solvent-free process that results in zero VOC emissions.

As part of the powder coat process, all parts are cleaned and de-greased in a light acid wash bath.

In a second step, parts are dipped in a phosphate bath to inhibit rust and improve powder adhesion.

In a final step, parts are finished using an innovative method that deposits a 2-3 times thicker material layer onto the product vs traditional spray coating.

The thicker coating results in a better seal on the edges, and in the mesh corners. The result is a more durable finish that offers better long term protection against moisture and rust.